Cocoa butter or cacao butter (CB) is an oil with special functions obtained by pressing cocoa beans. It is a milky yellow solid at room temperature, similar in appearance to white wax, and has an aromatic smell. Cocoa butter is the ideal special oil for chocolate. So do you know how is cocoa butter manufactured?

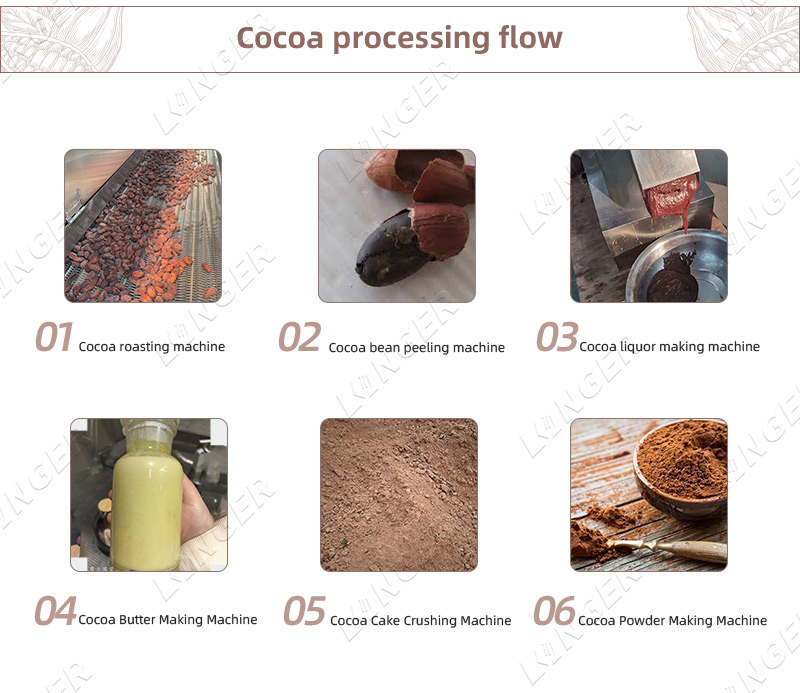

Cocoa Butter Manufacturing Process:

Cocoa beans start their transformation journey from cocoa plantations near the equator to cocoa factories or chocolate factories:

1. Select and remove impurities

It is mainly to pick out those cocoa beans of poor quality, and then remove some leaves, stones, sand and other debris that may be mixed in the harvest. Prevent damage to subsequent equipment and affect the cocoa finished product.

2. Roasting

Roast cocoa beans at 120 degrees Celsius for about 30 minutes. Roasting can further remove some of the moisture, while giving the cocoa beans a rich, aromatic flavor. The roasting step is a key step that affects the cocoa finished product as well as the chocolate flavor, and also makes it easier to remove the rind of the cocoa beans. You need to choose a good cocoa bean roasting machine.

3. Crushing and peeling

Cocoa husks need to be removed because cocoa husks are rich in tannins and other unpleasant taste components. The roasted cocoa bean skin becomes hard and crisp, and after entering the peeler, it is crushed and becomes cocoa nibs. At the same time, the fan will also suck away the cocoa bean skin to get clean cocoa nibs.

4. Grinding

The cocoa nibs are poured into the grinder, and the thick substance produced by fine grinding is cocoa liquor sauce, which condenses into lumps after cooling, which is cocoa liquor mass. The fineness of cocoa sauce generally reaches 100 mesh. Cocoa mass has a fat content of more than 50% and is the main raw material for making chocolate.

5. Pressing

Put the cocoa mass into the cocoa butter press for pressing, the pressing pressure can reach 60Mp, and finally obtain cocoa butter with a fat content of 100%. According to production requirements, the time and pressure of pressing can be adjusted to control the fat content in the remaining cocoa cake.

The above is the cocoa butter manufacturing process. Cocoa butter is a natural fat in cocoa beans that does not raise blood cholesterol. And give chocolate its unique smoothness and melt-in-your-mouth properties. Physical and chemical indicators of cocoa butter: moisture < 0.15%, refractive index 1.4577 ~ 1.4585, melting point 29 ~ 35 ℃, iodine value 33.5 ~ 37.5, saponification value 192 ~ 197.