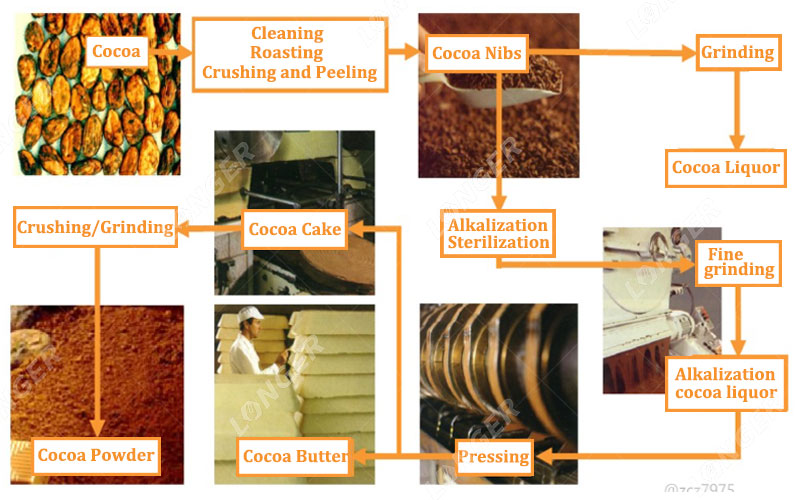

Cocoa powder has a strong and pure aroma and is an important raw material for chocolate, beverages, ice cream, candy, cakes and other foods. Let’s walk into the plant today to understand the cocoa powder manufacturing process.

Cocoa Powder Manufacturing Process – 9 Processes

1. Acceptance and Storage of Cocoa Beans

After the cocoa beans arrive at the cocoa plant, the first inspection is carried out, such as key ingredients and flavor indicators, cocoa bean quality, etc., the cocoa beans should be inspected according to the production requirements of the enterprise. Qualified cocoa beans should be stored in time, generally in a cool and dark place.

2. Impurity Removal

Because cocoa beans will have a lot of impurities when they are purchased and fermented, cocoa beans must be cleaned before entering the next process. Remove debris such as stones, dirt and sand from the cocoa beans.

3. Roasting

The cleaned cocoa beans are transported into the roasting machine through pipes or other lifting equipment. Typically roasting at a temperature of 120 to 160 degrees Celsius, it further removes moisture and produces characteristic aromas, while also making it easier to grind the cocoa beans and remove their skins.

4. Peeling

Roasted cocoa beans generally go into the peeling process, which is an important part of producing high-quality cocoa powder. After peeling and separating the kernels, the outer skin of the cocoa beans is completely removed, and only the cocoa nibs go to the next process.

5. Grinding and Slurry Storage

The peeled cocoa beans go into a colloid mill for coarse grinding. The coarsely ground cocoa beans will become its slurry, and the cocoa paste particles generally reach 100 mesh. These slurries go into slurry tanks for storage. The storage temperature will generally drop to 80 degrees Celsius.

6. Sterilization / Alkalization

The slurry must be sterilized before entering the next process. The sterilization temperature is generally above 121 degrees Celsius, and the time is more than 10 minutes. Only in this way can the bacteria in the slurry be basically eliminated. According to the needs of production, alkalized cocoa powder is generally alkalized in this place (or not alkalized according to production needs).

7. Fine Grinding (optional)

The cocoa slurry that has been sterilized/alkalized is also refined. Because the fineness of cocoa powder used in production generally exceeds 99%, this requirement can only be achieved by finely ground cocoa slurry. During the refining process, the temperature of the cocoa slurry will gradually decrease, and eventually it will drop to about 80 degrees Celsius.

8. Hydraulic Pressing

The refined cocoa pulp will enter the hydraulic press (some companies are also screw presses) for pressing. The pressing temperature generally exceeds 100 degrees Celsius, and the working pressure is above 500 Bar. Cocoa mass and cocoa butter (crude oil) are obtained by pressing cocoa mass. According to production requirements, the time and pressure of pressing are adjusted to control the fat content in cocoa powder.

9. Grinding Cocoa Powder

After pressing, the cocoa cake can enter the grinding process. Cocoa cakes are thoroughly crushed and sieved through a 100 mesh/200 mesh sieve. Only the cocoa powder that passes through the sieve is a qualified product. After the cocoa powder passes through the sieve, it is filled, packaged, stored, and finally transported to each food manufacturer.

The whole cocoa powder manufacturing process is basically this. Some cocoa factories have higher requirements. In the production process, not only good cocoa beans are used, but also secondary sterilization.

For more information on the equipment required in the above process, please see our cocoa powder production line.

Email: [email protected]

WhatsApp/Mobile: +8615515597212

Sir/Madam

Kindly forward me cocoa powder process, featuring various stages, and the approximate costs of infrastructure for set up purposes.

Dear Dennis Nasia,

Glad to receive your message. I have sent an email to you, please kindly check and reply.

Best Regards,

Serena

Sir/Madam

Kindly forward me cocoa powder process, featuring various stages, and the approximate costs of infrastructure for set up purposes.

Thank you

Dewrs,

Kindly send me the cocoa powder process, featuring various stages, and the approximate costs of infrastructure for set up purposes.

Thanks

Khaled

I would like to get in touch with you about cocoa production kindly contact me through mail and share details about the cocoa manufacturing and production

Dear sir/maam

Kindly send me the cocoa powder process, featuring various stages, and the approximate costs of infrastructure for set up purposes.

Your prompt response will be highly appreciated.

Thank you