Cocoa powder is also a cocoa product obtained by direct processing of cocoa beans. Cocoa powder is widely used to make beverages, cakes, biscuits and other products, and is also an important chocolate raw material. So how to make cocoa powder from cocoa beans in the factory? The following will tell you the detailed cocoa powder-making process.

1. Sampling analysis

After the cocoa beans arrive at the factory, they are first sampled for analysis, such as key ingredients and flavor indicators. Then, according to the product formulation requirements, cocoa beans of different varieties or origins are mixed. This process will determine the characteristic taste and flavor of each chocolate product, such as the body aroma that African cocoa beans can bring to chocolate, America and Asia. Cocoa beans can impart a refined aroma to chocolate.

2. Impurity removal

Wash debris such as stones, dirt and sand from the cocoa beans. Because cocoa beans have a lot of impurities when they are harvested, dried and fermented on the farm.

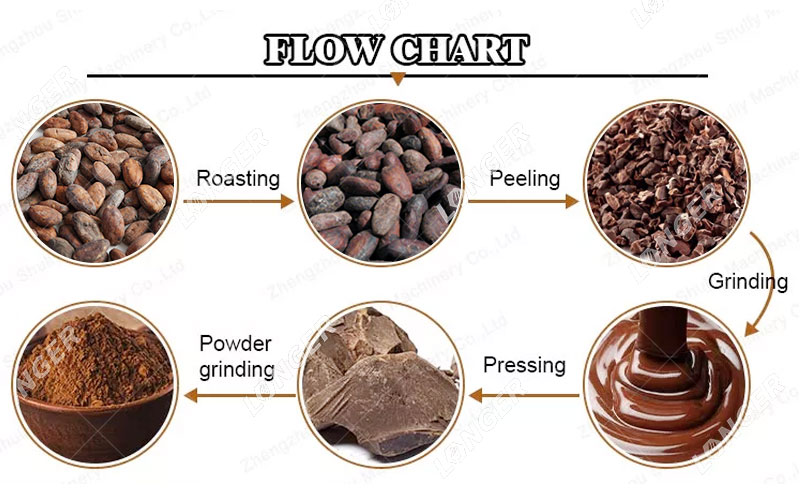

3. Roasting cocoa

Roasting the cocoa beans further removes moisture and produces characteristic aromas. Generally, the roasting temperature is between 120 and 160 degrees Celsius. This step is an important step to produce high-quality cocoa products, so the quality and technical requirements of the cocoa bean roaster are very high.

4. Winnowing and Peeling

The roasted cocoa beans begin the peeling process, which produces cocoa nibs. After air-selection, peeling and kernel separation, the outer skin of the cocoa beans is completely removed. Some factories will package some of the cocoa nibs and sell them directly; some will continue to further processing.

5. Grinding

The peeled cocoa nibs enter a colloid mill for grinding to become cocoa slurry, and the fineness of cocoa sauce generally reaches 100 mesh. Then the cocoa sauce will go into the holding tank for storage and continue to the next step of processing. The storage temperature is generally lowered to 80 degrees Celsius to prevent the cocoa paste from solidifying.

6. Oil pressing

The cocoa paste is put into a press filter bag and then put into a hydraulic press for pressing. The pressing pressure can reach 60Mpa. The oil overflows under high pressure through a very fine sieve, resulting in a silky and fine cocoa butter.

7. Powder grinding

The solids in the cocoa liquor are left in the column in a “cake-like” form, which is the cocoa cake. After the pressing process, the cake-like solids are made into cocoa powder through a series of grindings. The particle size of cocoa powder is very important to the taste and flavor of the finished product. The smaller the particle size, the finer the taste and the more fully released the flavor.

Above is the process of making cocoa powder from cocoa beans. A simple summary is: cocoa beans are roasted and peeled to obtain cocoa nibs; cocoa liquor is obtained by grinding; cocoa cake is obtained after removing part of the cocoa butter from the cocoa liquor block; the cocoa cake is pulverized and sieved to obtain cocoa powder.

We supply the entire cocoa powder production line, welcome to inquire:

Email: [email protected]

WhatsApp/Mobile: +8615515597212